Fully Customizable

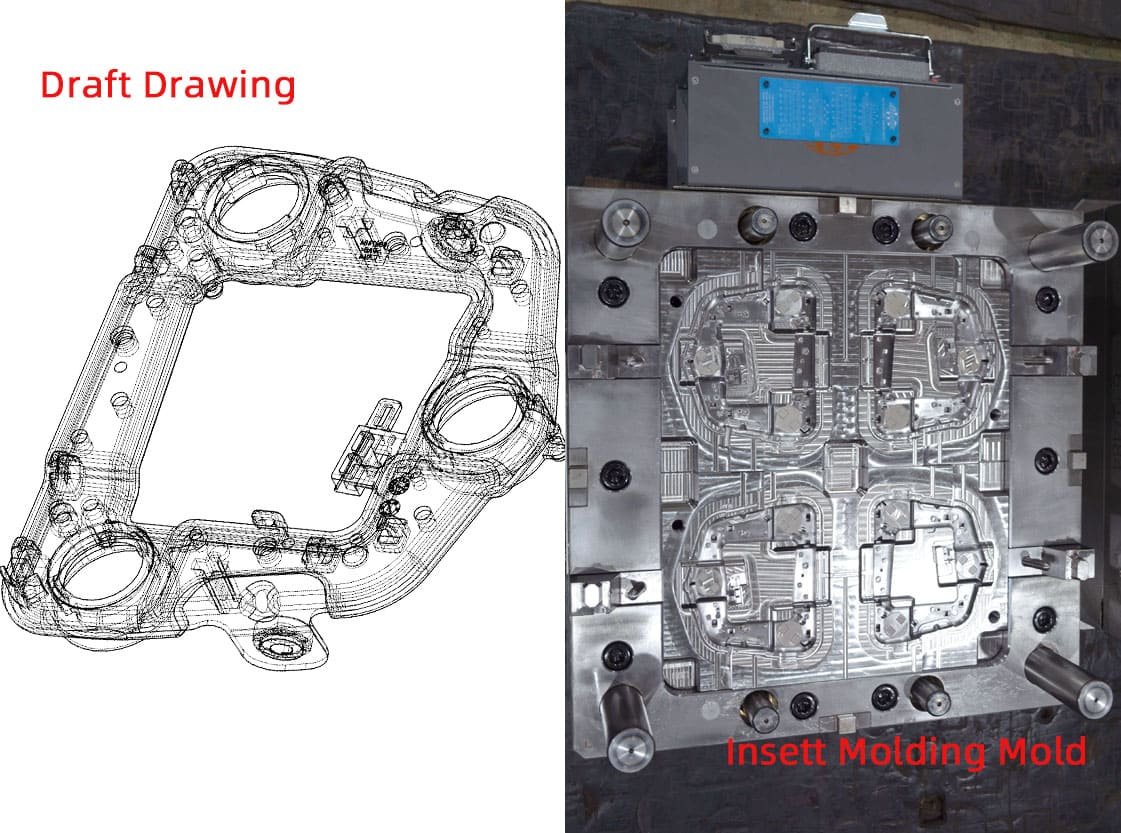

Custom Making your Insert Molding Project

Whether it’s designing high-precision insert molds for your product or delivering high-quality molded parts, we’re your trusted insert molding solution provider.

- 100% Feasibility Analysis: Comprehensive evaluation before production

- ±0.01mm Mold Precision: High-accuracy CAD/CAM design and validation

- 100% Material Inspection: Strict quality control for raw materials

- 9-Step Quality Check: Full-process monitoring from mold to molding

- 98% On-Time Delivery: Efficient production management and execution

- 24/7 Customer Support: Continuous improvement and rapid feedback response